The debate about automation and human labour now shapes the future of Costa Rica’s textile industry. Sector growth depends on a smart combination of digital tools and skilled workers, not on replacing one with the other. Balanced integration of automated systems, manual craftsmanship, and semi-digital processes supports productivity while protecting employment and economic stability. Industry associations such as CATECO promote this balanced model to help firms adapt to global expectations.

Meaning of Automation in the Textile Industry

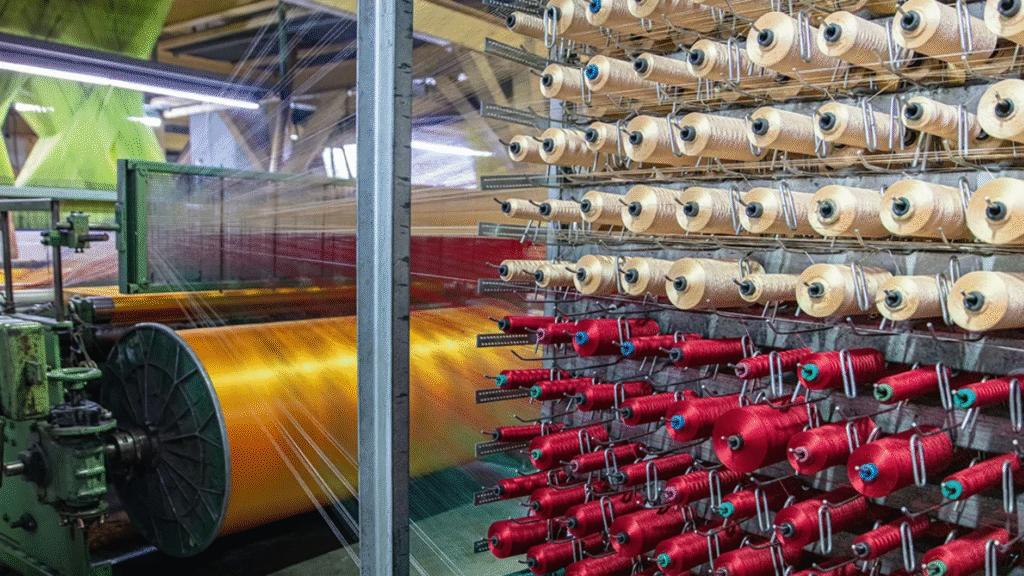

Automation in textiles refers to machines and digital systems that complete tasks with minimal manual intervention.

Key Features of Automation

- High-speed cutting machines controlled by software

- Automatic sewing equipment for repetitive stitching patterns

- Digital printing systems are replacing manual screen printing

- Robotic material handling for lifting and transporting rolls

- Production-planning software that schedules orders accurately

- AI-based quality control that identifies defects in real time

Automation reduces human strain and improves technical precision.

Role of Human Labour in Textile Production

Human labour remains essential even as automation grows.

Elements of Human Contribution

- Creative design skills that machines cannot replicate

- Quality checking that depends on human intuition

- Complex stitching requiring hand-guided precision

- Repair and maintenance of machinery

- Supervision to ensure safe and consistent production

- Adaptability to manage diverse production needs

Human workers bring judgment, flexibility, and experience to textile processes.

Benefits of Automation for Costa Rican Textile Plants

Automation helps firms become more competitive in global markets.

Major Advantages

- Higher productivity with faster cutting and stitching cycles

- Better accuracy in pattern making and fabric alignment

- Lower material waste through precise cutting technologies

- Improved safety as machines handle heavy lifting

- Energy savings through smart machinery

- Consistent quality across large orders

Automation also helps firms work within tight export deadlines.

Benefits of Human Labour for the Industry

Human skills still create value in areas machines cannot fully replace.

Human Advantages

- Craftsmanship that reflects experience and creativity

- Detailed finishing that requires personal judgement

- Quick adaptation to small-batch orders

- Problem-solving when unexpected technical issues occur

- Team-based operations that support workflow coordination

- Local employment that strengthens communities

Human labour preserves Costa Rica’s social and economic balance.

Challenges of Automation in Textile Plants

Automation brings benefits but also introduces certain challenges.

Key Challenges

- High investment cost for advanced machines

- Maintenance expenses that require specialised technicians

- Skill gaps for workers who must learn digital tools

- Limited flexibility in extremely customised products

- Risk of job displacement in repetitive tasks

- Dependency on technology during power or software failures

Costa Rican firms must evaluate these aspects before adopting full-scale automation.

Challenges of Human Labour in the Sector

Human involvement, although valuable, has limitations.

Key Human-Side Challenges

- Lower speed compared to automated machines

- Possibility of human error in repetitive tasks

- Physical fatigue from long hours or poor ergonomics

- Higher labour costs due to legal wage standards

- Training needs for new machinery

- Difficulty maintaining consistent output for large orders

Balanced systems help overcome these limitations.

Role of CATECO in Balancing Automation and Labour

CATECO supports firms in maintaining a productive mix of automation and skilled workers. CATECO Contributions

- Training programs on digital machinery and software

- Workshops on human–machine collaboration

- Guidelines for safe use of automated equipment

- Support networks connecting firms with technology suppliers

- Skill-development pathways for technicians

- Policy guidance to ensure fair employment practices

CATECO ensures that automation does not replace but complements the workforce.

Comparison of Automation and Human Labour

| Aspect | Automation | Human Labour |

|---|---|---|

| Speed | High speed with continuous output | Moderate speed with variability |

| Precision | Very accurate and consistent | Accurate but dependent on skill level |

| Flexibility | Limited for special tasks | Highly adaptable |

| Cost | High initial investment | Recurring wage expenses |

| Creativity | Low creative ability | Strong creative judgement |

| Safety | Reduces heavy lifting and hazards | Requires safety training and monitoring |

Areas Where Automation and Human Labour Work Together

| Process Area | Combined Contribution |

|---|---|

| Cutting | Automated cutters improve accuracy while humans manage layout and adjustments. |

| Stitching | Machines sew basic seams while workers guide complex operations. |

| Finishing | Automated presses improve speed while humans ensure final quality. |

| Quality Control | Digital scanners detect defects while humans confirm the final decision. |

| Inventory Handling | Robots move materials while staff manage planning and documentation. |

Balanced Model for Costa Rican Textile Plants

Costa Rican textile firms benefit most from a hybrid model where automation increases efficiency and human labour increases adaptability.

Elements of a Balanced Model

- Automation for repetitive, high-volume tasks such as cutting and basic stitching

- Human labour for creative and customised tasks requiring unique judgement

- Shared roles in quality control combining machine detection and human evaluation

- Technical upskilling to help workers operate automated tools

- Clear job roles that define when machines lead and when workers support

- Sustainable employment planning that protects jobs while adopting new technology

Balanced systems support long-term industry growth.

Impact on Employment and Skills

Employment patterns change when automation increases, but new opportunities also emerge.

Expected Changes

- New technical jobs for machine operators and digital designers

- Higher demand for maintenance technicians

- Reduced need for repetitive manual roles

- Upskilling programs to prepare workers for digital environments

- Greater emphasis on problem-solving and creative skills

Costa Rica’s workforce can transition smoothly with proper training support.

Future Trends in Automation and Labour Relations

Future developments indicate deeper integration of technology and human capabilities.

Expected Trends

- AI-assisted design tools supporting designers

- More digital sewing stations with semi-automatic guidance

- Greater use of sensors to reduce errors

- Virtual training labs for worker skill building

- Robotics in logistics supporting material movement

- Sustainable automation focusing on energy efficiency

The future of Costa Rica’s textile sector lies in smart, human-centred innovation.

Wrapping Up

Balanced use of automation and human labour strengthens Costa Rica’s textile sector by combining efficiency with creativity. Industry progress depends on technology-driven systems supported by skilled workers who maintain flexibility and problem-solving capacity. Continued training, responsible adoption of machinery, and guidance from CATECO will help the industry achieve competitiveness while protecting meaningful employment.