A rapid technological shift is transforming how Costa Rican textile factories operate, compete, and plan for the future. A growing dependence on automation reflects the industry’s commitment to quality, efficiency, and precision. A modern industrial landscape now prioritizes digital integration, smart machinery, and streamlined workflows to meet rising international standards and overcome traditional limitations.

Digital Transformation Reshaping Production

A decisive movement toward digitalization has redefined factory operations across the textile chain.

- Integration of software platforms that coordinate procurement, production, and delivery

- Real-time tracking of machine performance to reduce downtime

- Digital visualization tools are used to simulate fabric behavior before production

- Automated scheduling programs that optimize work orders and staffing

- Cloud-based storage systems supporting design files and technical specifications

A digital-first mindset enables faster decision-making, better cost control, and stronger consistency in product quality.

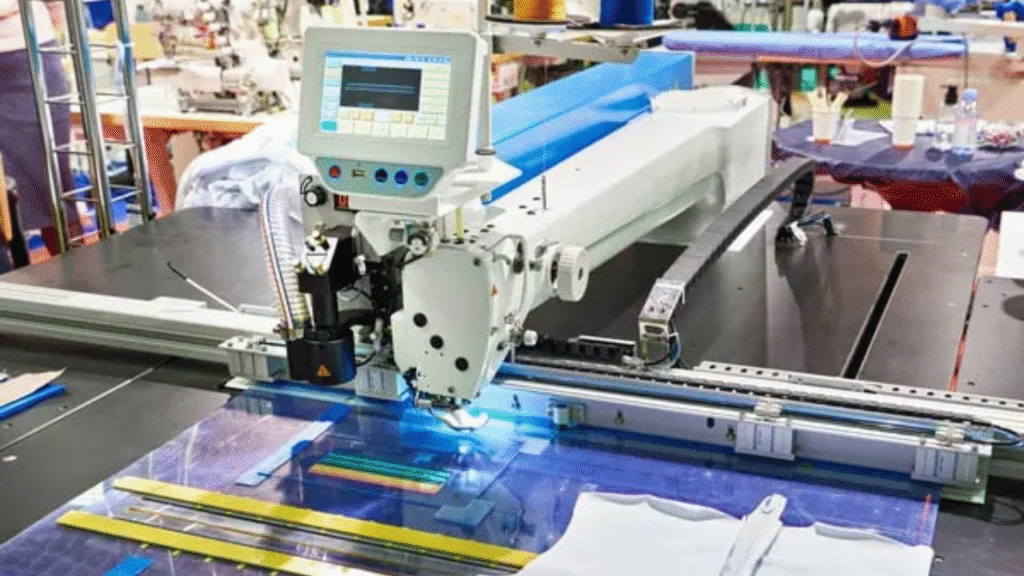

Automation of Cutting, Sewing, and Finishing

A wave of mechanization now supports the physical stages of textile production, replacing many repetitive manual tasks.

- Use of CNC cutting machines that reduce fabric waste

- Automated spreading systems ensure uniform fabric layers

- High-speed sewing robots are used for precise stitch patterns

- Robotic arms assisting with hem finishing and button attaching

- Laser-based finishing systems are improving accuracy in distressing and surface treatments

An efficiency-focused operational model increases output reliability while minimizing human fatigue and potential errors.

Key Automation Technologies in Use

Technology Overview

| Automation Area | Function |

|---|---|

| CNC Cutting | Delivers precise cuts and reduces material waste |

| Sewing Robotics | Provides consistent stitching and faster output |

| Laser Finishing | Enables detailed textures and specialized effects |

| Automated Spreading | Standardizes fabric layering across batches |

| Digital Patterning | Replaces manual paper patterns with software tools |

Design Innovation Through Digital Tools

A design revolution has emerged as technology enhances creativity and experimentation.

- Digital printing systems that allow complex artwork without screens

- CAD software enabling pattern designers to adjust sizing with precision

- 3D garment simulations showing drape, fit, and behavior before sampling

- Color-matching applications ensure consistency across production runs

- Digital archives storing seasonal design libraries for long-term use

A technology-enabled design workflow reduces sampling time and strengthens collaboration between designers, buyers, and production engineers.

Smart Quality Control Systems

A shift toward sensor-driven inspection has improved accuracy and reduced defective output.

- Camera-based systems scanning fabrics for imperfections

- Automated defect mapping that guides operators in real time

- Digital moisture and heat sensors ensure consistent curing conditions

- AI-driven quality scoring systems evaluating finishing stages

- Barcode-based tracking of each production lot from start to finish

A data-centered quality approach creates stronger product reliability and minimizes customer complaints.

Enhanced Traceability and Transparency

A visibility-focused supply chain is gaining importance as international buyers demand ethical and transparent sourcing.

- RFID tagging of fabric rolls and garment bundles

- Blockchain-based tracking systems for documenting each production stage

- Digital certification processes verifying eco-friendly inputs

- Electronic monitoring of dye-house chemistry usage

- Cloud platforms showing compliance documentation for audits

A strengthened traceability system reassures buyers about responsible manufacturing practices.

Benefits of Technology in Textile Traceability

Traceability Improvements

| Category | Benefit |

|---|---|

| Transparency | Clear visibility from raw material to finished garment |

| Compliance | Easier documentation for environmental and labor checks |

| Speed | Faster audit responses and shipment approvals |

| Error Reduction | Lower risk of mislabeling or incorrect reporting |

| Reputation | Stronger trust with global buyers and certification agencies |

Automation in Logistics and Material Handling

A modernized movement of goods ensures smoother internal and external logistics.

- Automated conveyors transporting fabric rolls and cut panels

- Warehouse management systems assign storage zones automatically

- GPS-enabled tracking for outbound shipments

- Robotic palletizers are reducing manual lifting

- Route optimization tools supporting efficient delivery plans

A streamlined logistics system reduces delays, improves worker safety, and ensures faster order fulfillment.

Workforce Transformation Driven by Technology

A shift in workforce roles reflects the integration of automation across the textile value chain.

- Increased demand for technicians who can maintain mechatronic equipment

- New roles in data monitoring, predictive maintenance, and process engineering

- Decline in some repetitive manual tasks has been replaced by semi-autonomous machinery

- Need for continuous training on digital platforms and automated systems

- Expansion of hybrid roles blending design, programming, and production management

A skill-focused transition positions workers to operate and supervise increasingly complex systems.

Sustainability Gains Enabled by Automation

A more resource-efficient production model emerges as factories replace outdated manual processes.

- Reduced energy usage due to optimized machine cycles

- Lower chemical waste from precision dosing technologies

- Less fabric waste because of accurate cutting and positioning

- Improved water savings via automated dyeing machines

- Real-time monitoring prevents unnecessary overproduction

A sustainability-driven technology strategy connects environmental responsibility with cost savings.

Investment Trends Supporting Technological Upgrades

A growing appetite for modernization shapes investment decisions across the sector.

- Purchase of advanced machinery funded through public and private incentives

- Renewal of production floors to accommodate automation lines

- Expansion of digital infrastructure for real-time monitoring

- Collaboration with universities for research on textile robotics

- Long-term investment in predictive maintenance systems

Challenges Linked to Technological Adoption

A set of operational obstacles accompanies the modernization process.

- High initial investment costs are limiting adoption by smaller factories

- Need for specialized training and continuous upskilling

- Complexity of integrating new machines with existing infrastructure

- Risk of overdependence on imported technological components

- Requirement for strong cybersecurity measures in cloud-connected systems

The Bottom Line

A technology-driven evolution now defines Costa Rica’s textile manufacturing landscape, reshaping production processes, design workflows, and quality control. A dynamic combination of automation, digital tools, and smart logistics strengthens competitiveness and improves sustainability outcomes. A forward-moving industry emerges as manufacturers build more efficient, precise, and globally aligned operations through continuous technological innovation.