The development of 3D textile preforms has transformed the field of composite materials, enabling higher structural performance, improved durability, and design flexibility. These preforms serve as the primary reinforcement in fiber-reinforced composites, widely used in industries such as aerospace, automotive, marine, and construction. Optimizing weave design and formability ensures that composites achieve superior mechanical properties while remaining manufacturable and cost-effective.

Overview

| Aspect | Impact on Composite Applications |

|---|---|

| Weave Design | Determines strength, stiffness, and load distribution |

| Formability | Ability to shape preforms without defects |

| Fiber Orientation | Influences mechanical performance and durability |

| Material Selection | Carbon, glass, or aramid fibers for specific applications |

| Thickness Control | Ensures uniform composite layers |

| Void Minimization | Reduces defects and enhances structural integrity |

Weave Design in 3D Textiles

Weave design plays a critical role in defining the mechanical behavior and load-bearing capacity of composite structures:

- Interlacing patterns create strength in multiple directions.

- Orthogonal, angle-interlock, and layered weaves allow customization for specific stress requirements.

- Proper weave selection ensures uniform stress distribution and reduces delamination risks.

Careful design of the weave is essential to achieve the desired balance of stiffness, strength, and flexibility.

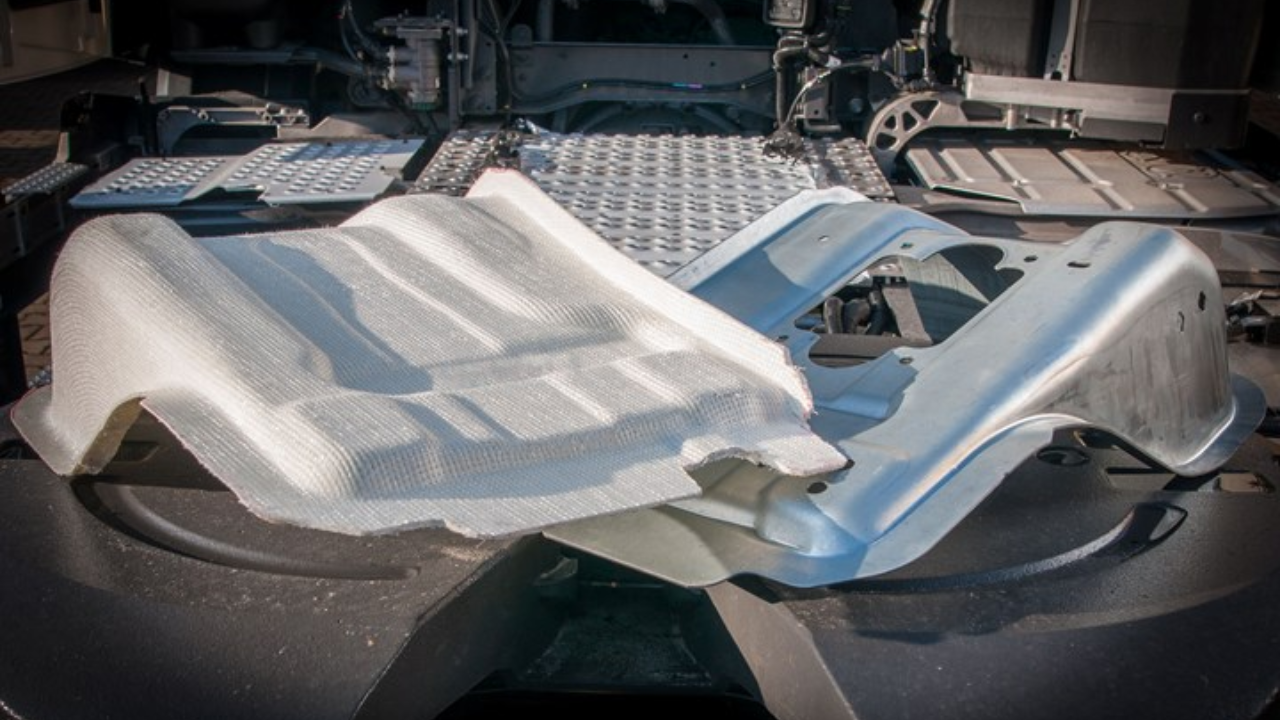

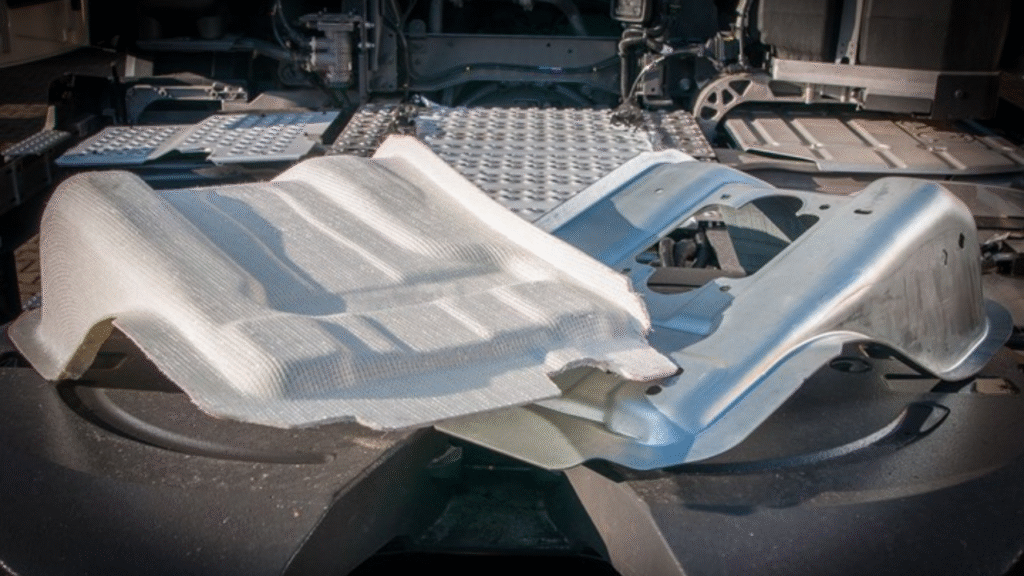

Formability of 3D Preforms

Formability refers to the ability of textile preforms to conform to complex geometries without defects:

- High formability enables efficient production of curved or contoured components.

- Influenced by yarn type, weave pattern, and fiber volume fraction.

- Advanced simulation tools predict performance behavior under tension and compression, reducing trial-and-error in manufacturing.

Ensuring high formability is crucial for consistent quality and structural integrity in finished composites.

Fiber Orientation and Mechanical Performance

Fiber alignment directly affects the strength, stiffness, and durability of composites:

- Unidirectional fibers maximize tensile strength along one axis.

- Multidirectional weaves provide balanced mechanical properties across multiple axes.

- Angle-interlock patterns improve shear strength and resistance to damage.

Optimizing fiber orientation ensures composites can withstand complex and multi-directional loading conditions.

Material Selection for Preforms

Selecting appropriate fibers is key to achieving both performance and cost efficiency:

- Carbon fibers offer a high stiffness-to-weight ratio, ideal for aerospace applications.

- Glass fibers provide cost-effective solutions with good strength.

- Aramid fibers enhance impact resistance for the automotive and defense sectors.

Correct material selection ensures composite components meet performance, safety, and durability requirements.

Thickness Control and Layering

Consistent thickness is critical for:

- Maintaining uniform mechanical properties throughout the component.

- Ensuring predictable resin flow during infusion or molding processes.

- Reducing weight variations in lightweight structures such as aircraft and vehicles.

Advanced layering techniques in 3D weaves allow tailored thickness for specific stress and load requirements.

Minimizing Voids and Defects

Defects such as voids, fiber misalignment, and wrinkles can compromise structural performance:

- Controlled weaving reduces resin-rich or fiber-poor zones.

- Preform compaction minimizes air entrapment during molding.

- Quality control and inspection ensure high structural integrity and consistent performance.

Reducing defects improves the durability, safety, and lifespan of composite components.

Applications of 3D Textile Preforms

3D textile preforms are increasingly used in industries demanding high-performance composites:

- Aerospace: Wing panels, fuselage structures, and reinforcements.

- Automotive: Chassis, crash-resistant structures, and interior panels.

- Marine and Construction: Lightweight hulls, panels, and load-bearing components.

Optimized preforms enable the production of lightweight, high-strength structures that improve energy efficiency and overall performance.

Summing Up

The weave design and formability of 3D textile preforms are fundamental to producing high-performance composite materials. Optimizing fiber orientation, material selection, thickness, and defect control ensures lightweight, durable, and reliable components. Adoption of these advanced preforms allows industries to meet modern performance, safety, and sustainability standards, making them a cornerstone of contemporary composite manufacturing.

Frequently Asked Questions

Q: What are 3D textile preforms used for?

A: They are used as reinforcement structures in fiber-reinforced composites.

Q: How does weave design affect composite performance?

A: It determines strength, stiffness, and resistance to delamination.

Q: Why is formability important in preforms?

A: High formability allows shaping preforms without wrinkles or fiber misalignment.